VA phase solvent

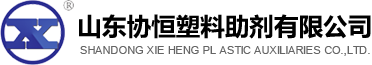

VA compatibilizer is a linear macromolecule with high specific surface area and ultra-high molecular weight obtained by emulsion polymerization and spray drying, which is composed of acrylic acid monomer and VCM (vinyl chloride) with better compatibility with PVC.

Category:

VA compatibilizer

Key words:

VA phase solvent

Details

Production introduction

VA compatibilizer is a linear macromolecule with high specific surface area and ultra-high molecular weight obtained by emulsion polymerization and spray drying, which is composed of acrylic acid monomer and VCM (vinyl chloride) with better compatibility with PVC. In the thermoplastic molding process of PVC, VA compatibilizer has a strong interaction with PVC macromolecular chain and ACR foaming modifier, which is similar to thousands of physical cross-linking (considerable increase of PVC and foaming modifier macromolecular chain length), so that ACR foaming modifier and heat stabilizer can better exert its efficacy, and ultimately can significantly improve the melt strength of various rigid PVC foamed products in the production and processing process.

This product is 25KG/bag, the external product is a plastic woven bag, and the inner packaging is a plastic bag. This product is non-toxic and non-corrosive solid powder. It is a non-dangerous product. It should be transported as a non-dangerous product and should be protected from sun and rain. This product is stored in a cool and ventilated place to prevent direct sunlight. The shelf life is 12 months. After passing the inspection after exceeding the shelf life, it can still be used. The manufacturer, trademark, product certificate, net product content, product batch number, etc. are indicated on the outside of the packaging bag.

This product is 25KG/bag, the external product is a plastic woven bag, and the inner packaging is a plastic bag. This product is non-toxic and non-corrosive solid powder. It is a non-dangerous product. It should be transported as a non-dangerous product and should be protected from sun and rain. This product is stored in a cool and ventilated place to prevent direct sunlight. The shelf life is 12 months. After passing the inspection after exceeding the shelf life, it can still be used. The manufacturer, trademark, product certificate, net product content, product batch number, etc. are indicated on the outside of the packaging bag.

Application features

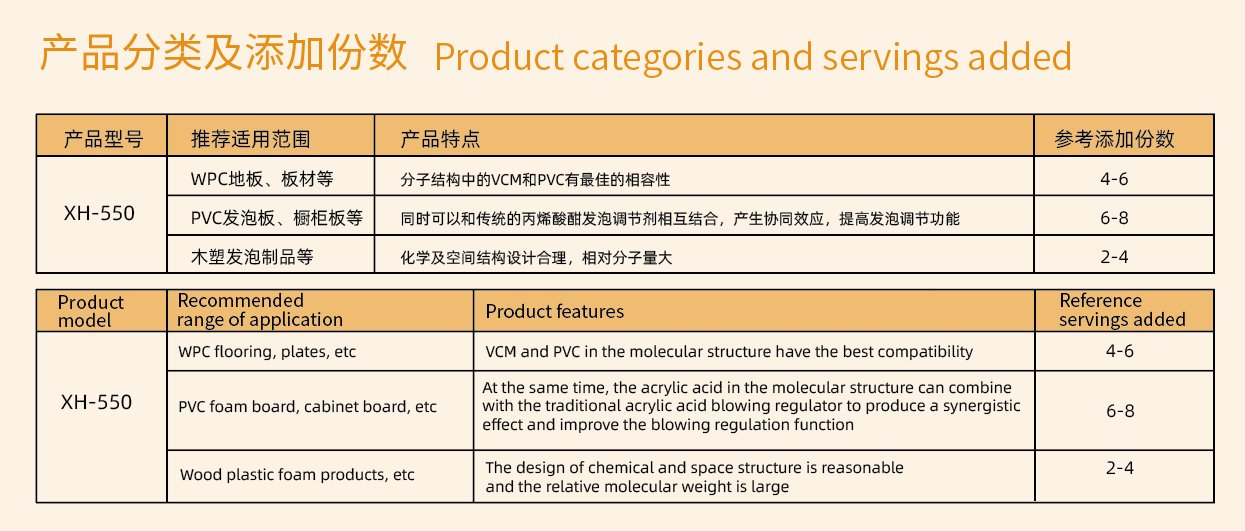

1. During the molding process, the uniformity of the PVC melt can be more effectively improved, thereby bringing excellent surface uniformity of the product.

2. With ultra-high specific surface area, the specific surface area of VA compatibilizer is about 100 times that of ordinary PVC, and the "bonding" area is large, which can bond together with PVC more quickly and play a better role in foaming adjustment.

3. It can significantly increase the melt strength of PVC, and effectively reduce the energy consumption in the PVC processing process and the use of traditional conditioners.

4. The recommended dosage is 30wt.% -70wt.% of the dosage of the traditional foaming regulator, and the corresponding dosage of the traditional regulator can be reduced when added.

2. With ultra-high specific surface area, the specific surface area of VA compatibilizer is about 100 times that of ordinary PVC, and the "bonding" area is large, which can bond together with PVC more quickly and play a better role in foaming adjustment.

3. It can significantly increase the melt strength of PVC, and effectively reduce the energy consumption in the PVC processing process and the use of traditional conditioners.

4. The recommended dosage is 30wt.% -70wt.% of the dosage of the traditional foaming regulator, and the corresponding dosage of the traditional regulator can be reduced when added.

Leave A Message

MORE RRODUCTS