PVC lubricant

Category:

PVC lubricant

Key words:

PVC lubrican

Details

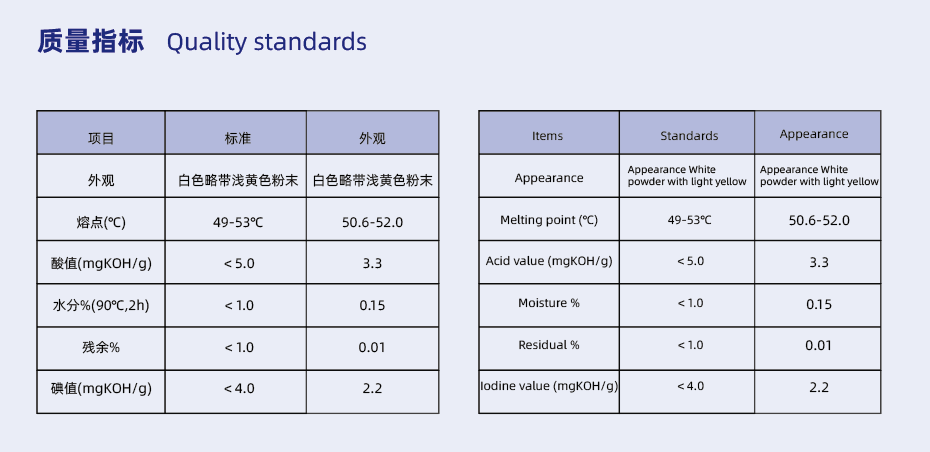

XH60 products are usually white/light yellow flaky solids or fluid powder waxes. They are neutral saturated fatty alcohol dicarboxylic acid values and can be dissolved in organic solvents such as ethanol and benzene. The advantage of the product is that it has complete varieties and specific functions. It can provide corresponding types of products according to customer needs, provide customers with a better lubrication system, and solve the problems of insufficient internal and external slip, imbalance of internal and external slip, and poor surface gloss, serious equipment wear and tear, and low production efficiency during product processing.

This product is 25KG/bag, the external product is a plastic woven bag, and the inner packaging is a plastic bag. This product is non-toxic and non-corrosive solid powder. It is a non-dangerous product. It should be transported as a non-dangerous product and should be protected from sun and rain. This product is stored in a cool and ventilated place to prevent direct sunlight. The shelf life is 12 months. After passing the inspection after exceeding the shelf life, it can still be used. The manufacturer, trademark, product certificate, net product content, product batch number, etc. are indicated on the outside of the packaging bag.

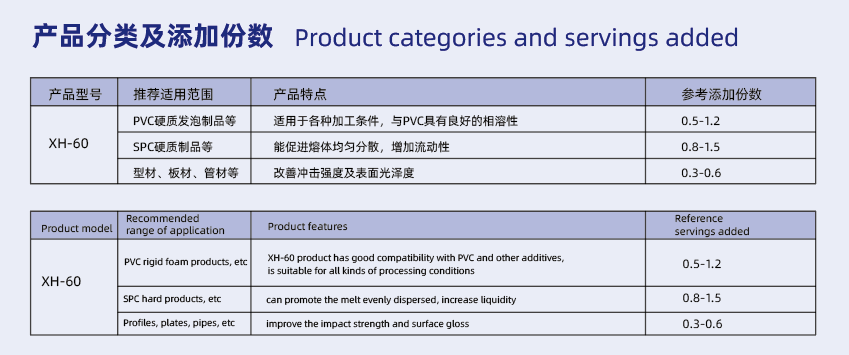

As an internal lubricant for the processing of rigid PVC products, XH60 product has good compatibility with PVC and other auxiliaries. It is suitable for various processing conditions. It can promote uniform dispersion of the melt, increase fluidity, improve impact strength and surface gloss. It can be widely used in transparent sheets, granules, profiles, plates, pipes, and engineering plastics. The addition amount is generally 0.3-1.2 parts, and it is appropriate to increase under special circumstances.

Leave A Message

MORE RRODUCTS