Composite stabilizer

Category:

Composite stabilizer

Key words:

Composite stabilizer

Details

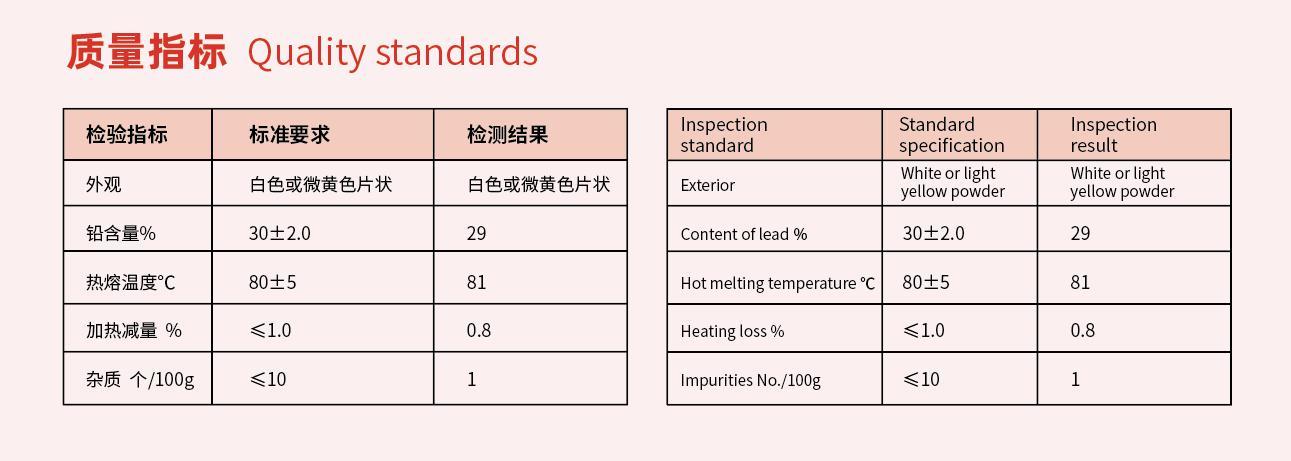

The composite stabilizer is composed of tribasic lead stearate, disalt lead sulfate, lead stearate, PE wax, stearic acid, and calcium carbonate through a special process. Such products have good adsorption properties, which can improve the whiteness of PVC products, shorten the time for PVC to remove HCL, reduce the amount of stabilizer, improve processability, weather resistance, stability, and reduce costs, so that the surface finish of the processed products has good physical properties, and the various components of the composite heat stabilizer can be fully mixed during its production process, which greatly improves the uniformity of mixing and dispersion with resin. Due to the good effect of thermal stability, especially the good long-term thermal stability effect, this type of stabilizer is widely used in the material production of PVC products.

This product is 25KG/bag, the external product is a plastic woven bag, and the inner packaging is a plastic bag. This product is non-toxic and non-corrosive solid powder. It is a non-dangerous product. It should be transported as a non-dangerous product and should be protected from sun and rain. This product is stored in a cool and ventilated place to prevent direct sunlight. The shelf life is 12 months. After passing the inspection after exceeding the shelf life, it can still be used. The manufacturer, trademark, product certificate, net product content, product batch number, etc. are indicated on the outside of the packaging bag.

2. This product has good coupling and solubilization function, enhances the compatibility of resin and filler, and reduces production costs.

3. This product has good lubrication and toughness, promotes melting, and has good plasticizing effect.

4. The hot mixing temperature of this product is 110~ 115 ℃

Leave A Message

MORE RRODUCTS