PVC processing aids

PVC processing aids are ultra-high molecular weight polymers with a multi-layer structure, which are made of acrylate monomers through multi-stage emulsion polymerization, which improves processing performance and has a stabilizing effect.

Category:

PVC processing aids

Key words:

PVC processing aids

Details

Production introduction

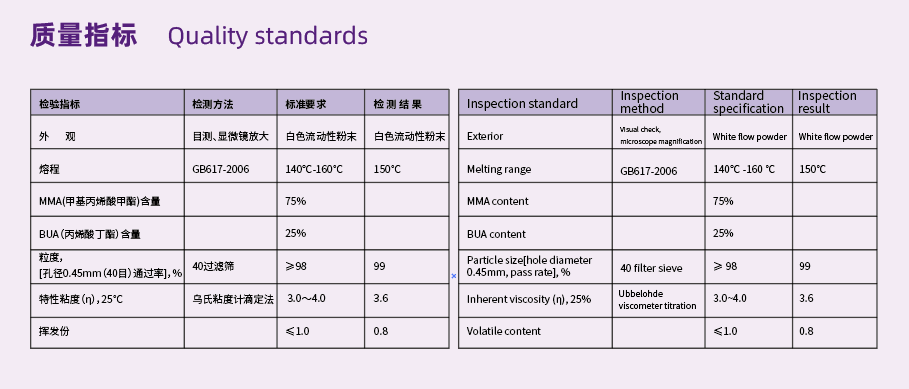

PVC processing aids are ultra-high molecular weight polymers with a multi-layer structure, which are made of acrylate monomers through multi-stage emulsion polymerization, which improves processing performance and has a stabilizing effect. The use of molecular sieves to modify processing aids not only improves the fluidity of the solution, thereby increasing the thermal strength and ductility of the solution, improving internal and surface quality, while shortening plasticizing time and increasing productivity.

This product is 25KG/bag, the external product is a plastic woven bag, and the inner packaging is a plastic bag. This product is non-toxic and non-corrosive solid powder. It is a non-dangerous product. It should be transported as a non-dangerous product and should be protected from sun and rain. This product is stored in a cool and ventilated place to prevent direct sunlight. The shelf life is 12 months. After passing the inspection after exceeding the shelf life, it can still be used. The manufacturer, trademark, product certificate, net product content, product batch number, etc. are indicated on the outside of the packaging bag.

This product is 25KG/bag, the external product is a plastic woven bag, and the inner packaging is a plastic bag. This product is non-toxic and non-corrosive solid powder. It is a non-dangerous product. It should be transported as a non-dangerous product and should be protected from sun and rain. This product is stored in a cool and ventilated place to prevent direct sunlight. The shelf life is 12 months. After passing the inspection after exceeding the shelf life, it can still be used. The manufacturer, trademark, product certificate, net product content, product batch number, etc. are indicated on the outside of the packaging bag.

Application features

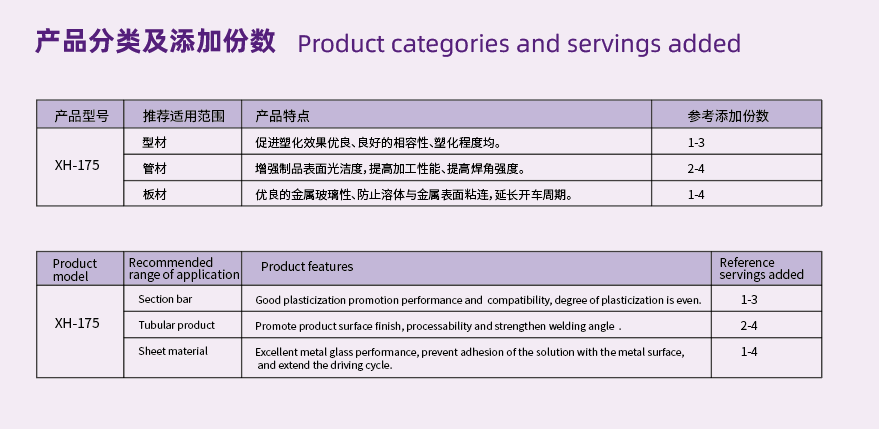

1. Excellent plasticizing performance, improve plastic fluidity.

2. Good weather resistance and slow aging time.

3. Reduce the swelling effect of release film, have strong resistance to elongation or extension deformation, and improve solution viscosity.

2. Good weather resistance and slow aging time.

3. Reduce the swelling effect of release film, have strong resistance to elongation or extension deformation, and improve solution viscosity.

Leave A Message

MORE RRODUCTS