Polyethylene wax

Category:

Polyethylene wax

Key words:

Polyethylene wax

Details

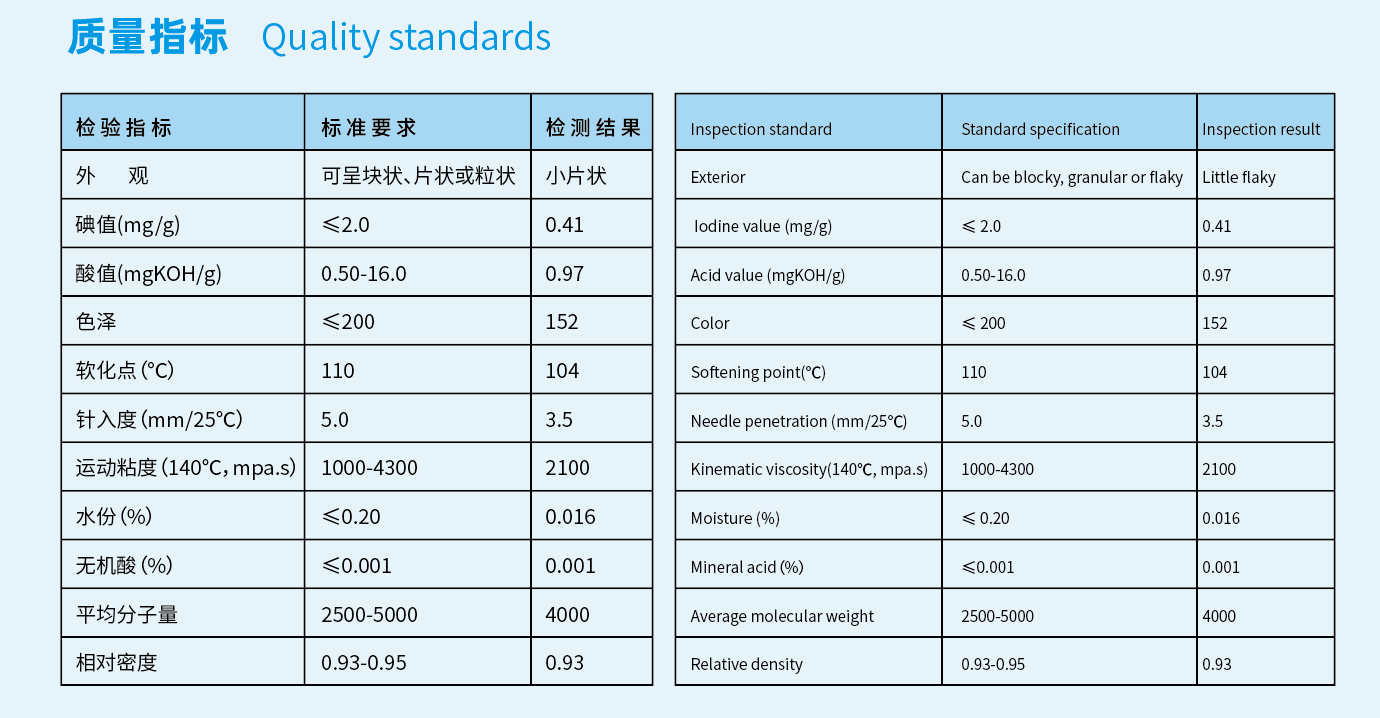

Polyethylene wax (PE wax), also known as polymer wax, is referred to as polyethylene wax. It is widely used because of its excellent cold resistance, heat resistance, chemical resistance and wear resistance. In normal production, this part of the wax can be directly added to the polyolefin processing as an additive, which can increase the gloss and processability of the product. As a lubricant, it has stable chemical properties and good electrical properties. Polyethylene wax has good compatibility with polyethylene, polypropylene, polyvinyl waxy acid, ethylene propylene rubber, and butyl rubber. It can improve the fluidity of polyethylene, polypropylene, ABS and the release of polymethyl methacrylate and polycarbonate. Polyethylene wax has stronger internal lubrication for PVC than other external lubricants.

This product is 25KG/bag, the external product is a plastic woven bag, and the inner packaging is a plastic bag. This product is non-toxic and non-corrosive solid powder. It is a non-dangerous product. It should be transported as a non-dangerous product and should be protected from sun and rain. This product is stored in a cool and ventilated place to prevent direct sunlight. The shelf life is 12 months. After passing the inspection after exceeding the shelf life, it can still be used. The manufacturer, trademark, product certificate, net product content, product batch number, etc. are indicated on the outside of the packaging bag.

1. Make dispersant in masterbatch processing.

2. Make external lubricants during the molding process of PVC products.

3. Used for ink, paper, plastic film, concentrated masterbatch, biodegradable double masterbatch, candle, etc.

Leave A Message

MORE RRODUCTS